Introduction

As drones slice through city skylines, patrol fields, or bring hope to disaster sites… we marvel at their powerful capabilities, yet often overlook the "invisible powerhouses" hidden beneath their sleek exteriors.

Today, we unveil a core material – Fiberglass Fabric. Like a pair of invisible wings, its super properties of being "light, strong, and stable" support every high-flying journey of a drone.

Part 1: The "Essential Flight Needs" of Drones – Why the Preference for Fiberglass Fabric?

A drone's performance consistently revolves around three core aspects: longer flight time (lightweight), stronger structure (strong), and greater reliability (stable).

Traditional aluminum alloy is too heavy, directly compromising precious battery life; whereas ordinary plastic is too "brittle," struggling to withstand high-altitude wind pressure and complex environments.

And Fiberglass Fabric is precisely the perfect "answer"!

Woven from glass fibers ten times thinner than a human hair, it possesses a "specific strength" (strength-to-weight ratio) far exceeding that of steel. More crucially, it combines multiple advantages like resistance to high and low temperatures, corrosion resistance, and strong insulation. Whether in the extreme cold of -50°C at high altitudes or exposed to pesticide corrosion in fields, it remains reliably in "service."

This combination of being "light yet strong, stable yet durable" makes it the ideal choice for drone materials.

Part 2: From Shell to Core, Fiberglass Fabric's "All-Round Application Showcase"

The application of fiberglass fabric is far from a simple material substitution; it's a structural reshaping of the drone from the outside in.

🛡️ Lightweight "Protective Armor" – Fuselage Shell

Drones need to "shed weight" but also be "impact-resistant." Fiberglass fabric combined with resin (GFRP) creates fuselage shells that weigh only one-third of equivalent-volume aluminum alloy shells, yet can withstand impacts several times their own force. Even in the event of accidental collisions during operation, they effectively absorb shock, protecting the internal core components from harm.

✈️ The "Foundation of Stable Flight" – Wings/Propellers

Wings and propellers, rotating at high speeds, have extremely demanding requirements for rigidity and fatigue resistance. Engineers lay multiple layers of fiberglass fabric at specific angles, enabling material strength to be "distributed on demand," effectively resisting centrifugal force and air resistance.

Data shows: An industrial inspection drone using fiberglass composite material wings achieved a 20% weight reduction and a 15% increase in flight time, while also gaining the ability to withstand Level 8 winds, significantly enhancing flight stability!

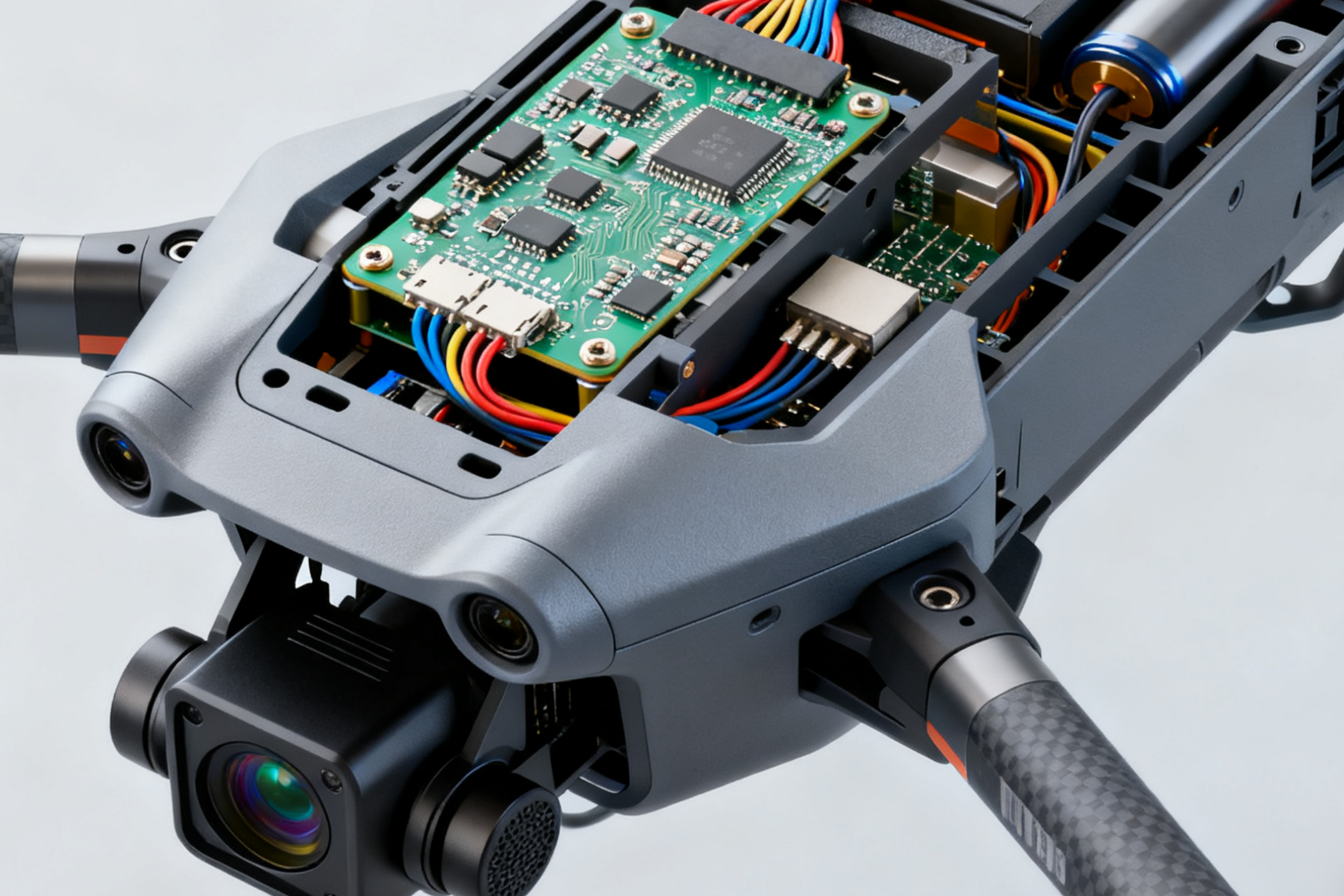

🔩 The "Invisible Support" for Precision Equipment – Internal Structural Components

Space inside a drone is at a premium, packed with delicate circuits and sensors. The excellent insulation properties and ease of molding of fiberglass fabric make it an ideal material for internal structural components like battery compartments and motor mounts. It provides robust support while effectively isolating electromagnetic interference, truly living up to its name as the "invisible support."

Part 3: Beyond That, It's Also Driving Drone "Evolution"

As drones advance into more specialized fields like heavy cargo transport and forest firefighting, fiberglass fabric is continuously "evolving" too.

"Powerful Alliance" with Carbon Fiber: On heavy-duty drones, it's used in hybrid composites with carbon fiber, ensuring ultra-high strength while balancing manufacturing costs, achieving ultimate cost-effectiveness.

Functional Coatings "Adding the Finishing Touch": By applying special coatings for fire resistance, UV resistance, etc., drones can confidently handle extreme environments like high temperatures in fire zones, multiplying their safety.

Mingyang Fiberglass: Injecting Core Strength into Flight Dreams

From consumer-grade to industrial-grade, every innovative application of fiberglass fabric relies on exceptional material technology and a stable supply chain behind it. As a leading supplier of electronic materials, Mingyang Fiberglass is a key force in this technological revolution.

Mingyang Fiberglass specializes in the R&D and production of high-quality fiberglass fabric. We provide not just materials, but also:

Ultimate Lightweight Solutions: Helping drones break through battery life bottlenecks, flying higher and farther.

Stable and Reliable Structural Support: Ensuring every drone can safely and efficiently complete its missions in harsh environments.

Future-Oriented Innovation Capability: Exploring the limitless potential of fiberglass materials in more cutting-edge fields like aerospace and new energy together with our partners.

Choosing Mingyang Fiberglass means choosing a future that is lighter, stronger, and more reliable.