Say Goodbye to Summer Heat, Save Every Kilowatt-Hour

In today's era where green buildings and energy conservation are becoming mainstream, how does one select a truly efficient and durable insulation material for construction? This not only concerns comfort but also directly impacts energy consumption and operational costs.

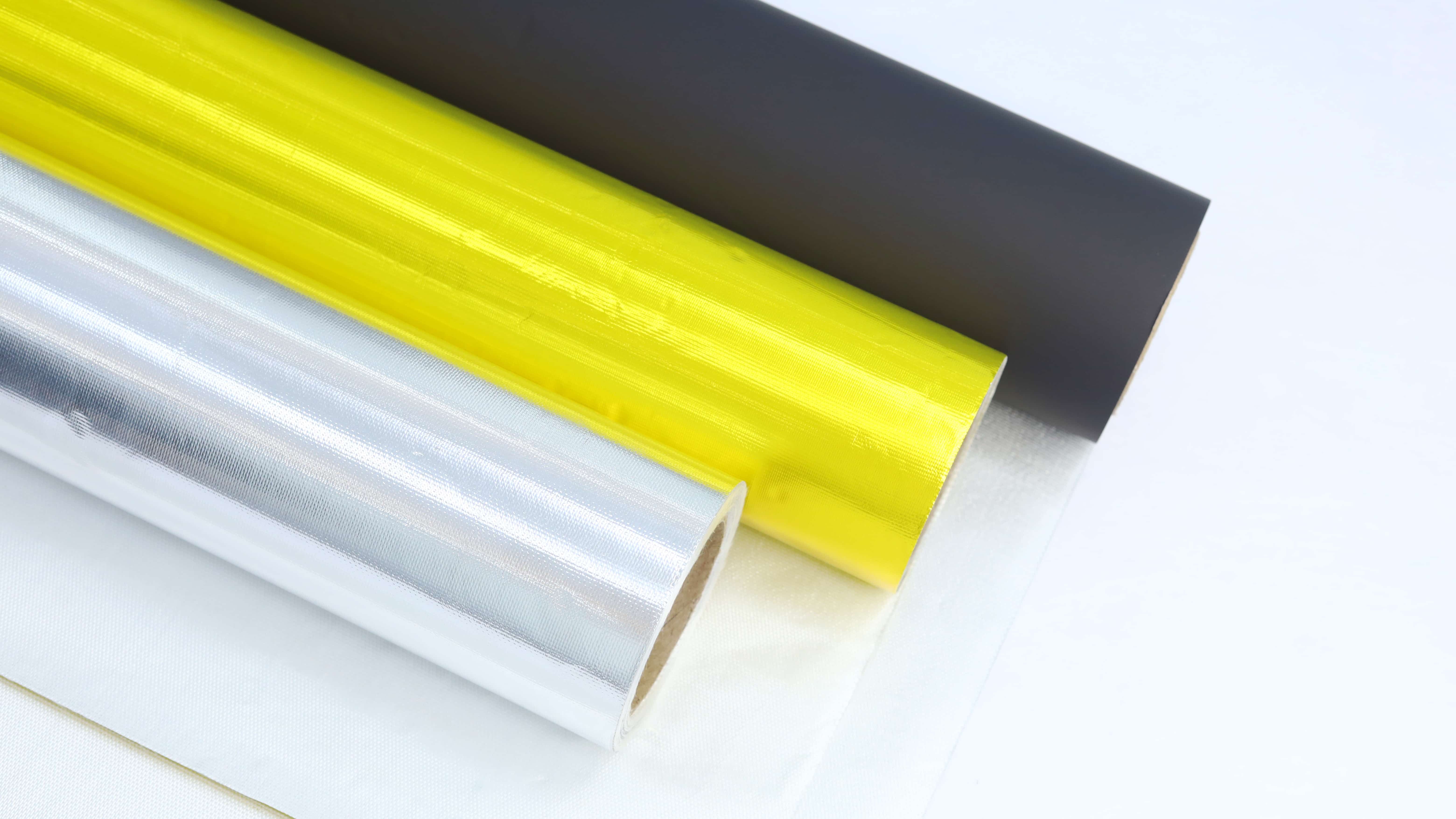

Today, let's introduce a highly favored material in the field of building insulation – Aluminum Foil Fiberglass Cloth. Let's see how it has become the ideal choice as a building's "insulating garment."

What is Aluminum Foil Fiberglass Cloth?

Simply put, this is an innovative composite material resulting from a "powerful alliance." It perfectly combines high-strength fiberglass cloth with high-purity aluminum foil, leveraging the advantages of both materials:

Base Material: Fiberglass cloth, providing excellent fire resistance, corrosion resistance, and outstanding tensile strength.

Surface Layer: Aluminum foil, offering powerful heat reflection and radiation barrier capabilities, along with excellent moisture and vapor barrier properties.

The combination of the two creates an ideal material that is both tough and durable, and possesses exceptional thermal insulation performance.

Four Core Advantages: Why is it Highly Favored?

1. High-Efficiency Insulation, Significant Energy Savings

The aluminum foil layer reflects over 90% of radiant heat, acting like an efficient "heat mirror" that blocks most heat from entering. Its use can significantly reduce indoor building temperatures, leading to a substantial decrease in air conditioning energy consumption.

2. Excellent Fire Resistance, Safe and Reliable

Fiberglass itself is a Class A non-combustible material, giving the product excellent fire performance. This effectively enhances building safety standards and adds a layer of protection for life and property.

3. Strong and Durable, Long Lifespan

The fiberglass cloth base ensures the material resists tearing and deformation, boasts good anti-aging properties, and is long-lasting, reducing long-term maintenance costs.

4. Moisture & Corrosion Resistance, Wide Applicability

The aluminum foil layer effectively blocks moisture vapor and corrosive gases, protecting internal structures and equipment. It is particularly suitable for humid or corrosive environments.

Diverse Application Scenarios, Making a Difference Everywhere

Industrial Plants & Steel Structure Buildings

Installed on roofs and walls, it forms an efficient thermal barrier. This not only significantly lowers indoor temperatures and improves the working environment but also greatly reduces energy consumption.

Pipeline & Equipment Insulation

Used as the protective outer layer for pipes, storage tanks, and HVAC ducts, it both prevents heat loss and protects the internal insulation material, serving the dual purpose of moisture proofing and physical protection.

Building Roof & Attic Insulation

In residential construction, used beneath sloped roofs, flat roofs, or in attic spaces to form a reflective insulation layer, effectively preventing summer solar heat from transferring indoors.

Other Specialized Fields

Also widely used in agricultural greenhouses, temporary structures, transport protection, and other areas, leveraging its multiple functions of insulation, sun shading, and protection.

Professional Manufacturing, Trustworthy Quality

Jiangxi Mingyang Fiberglass Co., Ltd., since its establishment in 2001, has consistently focused on the R&D and production of fiberglass products. As a leading producer of fiberglass and aluminum foil composite materials in Southern China, the company possesses a comprehensive quality control system and has passed ISO9001 and SGS certifications.

We not only provide high-quality Aluminum Foil Fiberglass Cloth products but also offer customers one-stop building insulation solutions. From raw material selection to production processes, every step is strictly controlled to ensure stable performance and a complete range of specifications for all outbound products.