Strengthening the Safety Cornerstone, Deepening Lean Management

On November 26, 2025, Jiangxi Mingyang glass Fiber Co., Ltd. (hereinafter referred to as "Mingyang glass Fiber") successfully convened its November Lean Production Coaching Session. The purpose of this meeting was to further solidify the company's achievements in safety production and quality management, address practical pain points on the production floor, and lay a solid management foundation for business expansion into high-end sectors such as new energy and shipbuilding. This was achieved through systematic on-site gemba walks, project reporting, and expert coaching.

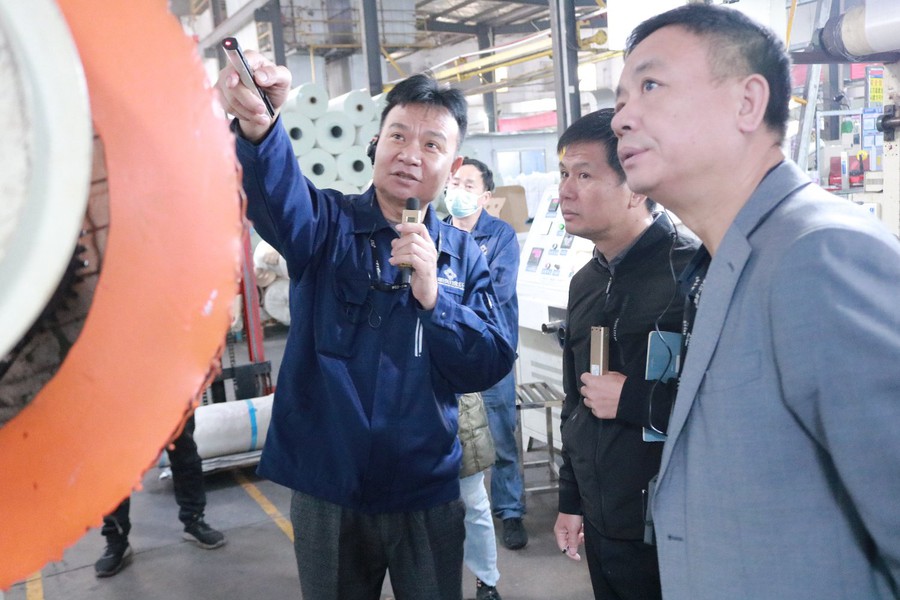

The session was led by Mr. Jiang, a senior lean management expert. Mr. He, the company's General Manager, attended the meeting and provided crucial commentary. Management personnel at all levels participated throughout.

Confronting Issues, Ensuring Orderly Production Progress

The meeting commenced at 9:00 AM in an atmosphere characterized by rigor and pragmatism. Supervisor Huang Xingzong, representing the administrative office, initiated the proceedings with a work report. The report indicated that overall production is currently proceeding in an orderly fashion, with all capacity indicators steadily advancing. However, certain "waste issues" persist in the details of production processes, leaving room for improvement and enhancement.

Following the report, the coaching team and the management team conducted an extensive two-hour on-site gemba walk. The walk-through was comprehensive, covering a special inspection based on the "Three Noes & One Specialization" principle, the First Article Inspection process, the implementation status of workstation safety protocols, and the operational reality of the 5-element visual boards based on TWI training. Through this "go and see" observation, management gained a more intuitive and profound understanding of the actual conditions on the production front line.

Vigilance in Safety, Upholding the Red Line

As of the meeting date, Mingyang Fiberglass had achieved a remarkable 458 consecutive days with zero work-related injuries. Mr. Jiang acknowledged the company's current efforts in production safety management but also issued a stern warning.

Mr. Jiang emphasized: "It is easier to conquer than to maintain." This impressive figure represents both an honor and significant pressure. He stressed that the awareness that "safety is the top priority" must not be weakened in the slightest. Addressing the core pain point of "insufficient sustainability" currently faced in 5S management, Mr. Jiang proposed four specific improvement requirements:

1. Cultivate Habits: Internalize standardized operations into employees' muscle memory.

2. Enhance Visualization: Implement standard visual management to make problems immediately apparent.

3. Exercise Leadership: Team leaders must lead by example and guide the overall skill improvement of frontline workers.

4. Deepen TPM: Thoroughly integrate the principles of Total Productive Maintenance (TPM) into daily work routines.

Leadership Insights: Looking Beyond the Surface

Concluding the session, General Manager Mr. He, in his summary remarks, set forth higher-level expectations for all management personnel. Mr. He emphasized that lean production must not be merely superficial; it is essential to "grasp the fundamental nature of operational and production problems." He urged managers at all levels to approach their work with thoroughness and steadfastness, focusing not only on data but also on employee development.

"Focus on your own improvement, and equally on the improvement of your employees." Mr. He pointed out that management should proactively engage in learning from the perspective of the company's long-term development, enhancing the team's overall capabilities to better respond to changes in the market environment.

Conclusion: Serving the Globe with Lean Quality

As a leading-scale producer of glass fiber and aluminum foil composite materials in Southern China, Mingyang Fiberglass steadfastly adheres to the high standards of the ISO9001 quality control system. From core products like aluminum foil glass fiber and aluminum foil glass fiber tape to emerging products serving the fireproof insulation needs of new energy vehicles, every lean production coaching session is aimed at fulfilling our commitment to provide global customers with the "one-stop procurement" of high-quality services.

Moving forward, Mingyang glass Fiber will continue to deepen lean management, transforming "safety competency" and "5S sustainability" into core competitive advantages, ensuring steady and sustained progress on the path of high-quality development.

END

Continuously providing high-quality products and services to our customers, contributing Mingyang's strength to the development of the new energy market!