To continuously deepen the understanding of lean production principles and comprehensively enhance factory operational efficiency and management standards, Mingyang Fiberglass successfully held its monthly Lean Production Special Guidance Activity on October 28, 2025. The event featured a special on-site guidance session by veteran lean production expert, Mr. Jiang, with the participation of all levels of management, collectively learning and practicing the essence of lean management.

The activity officially commenced at 9:00 AM. First, the administrative office delivered a detailed report to all participants on the current overall operational status of the factory, providing a realistic context for the subsequent learning and discussion. Following this, Mr. Jiang gave an important speech, strongly emphasizing the paramount importance of production safety. Mr. Jiang pointed out that safety is the cornerstone of enterprise production and an inviolable red line. He reminded all managers that they must not develop any sense of complacency or negligence due to the current good record of 'zero accidents'. Instead, they must keep the alarm bells ringing and implement safety awareness into every detail of production.

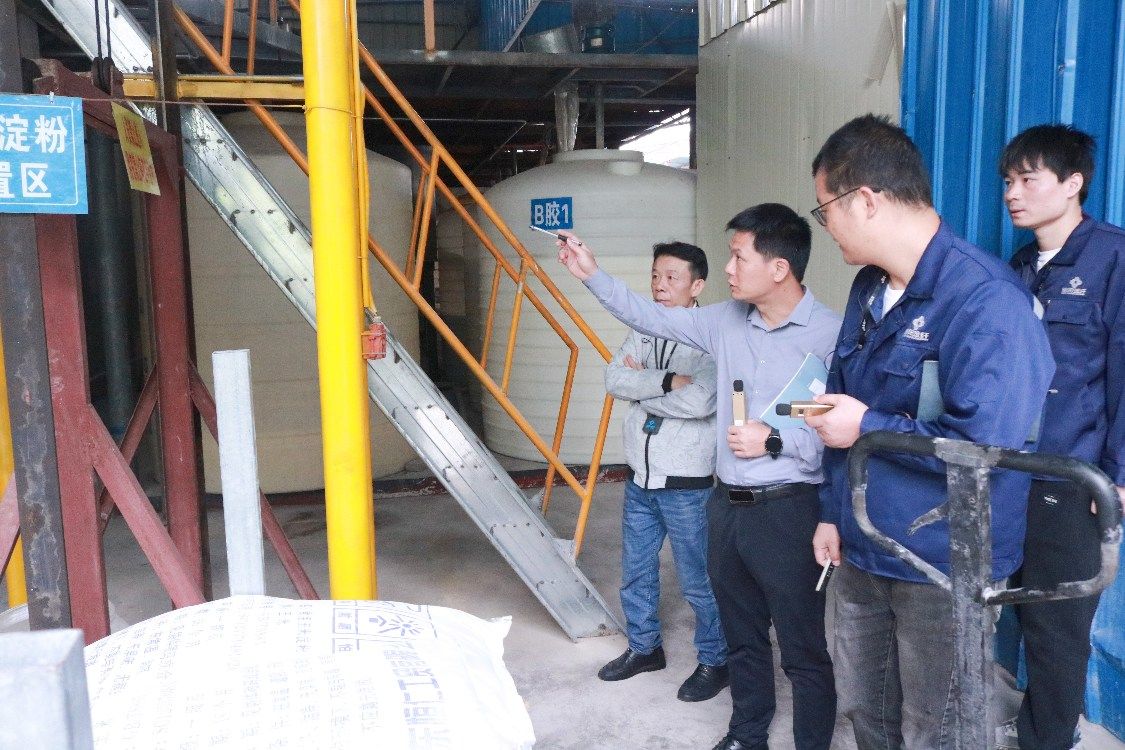

After the theoretical learning session, Mr. Jiang led all management personnel deep into the production front lines to conduct a comprehensive on-site inspection. This inspection incorporated the requirements of core lean tools such as TPM (Total Productive Maintenance) and TWI (Training Within Industry), focusing on reviewing the rectification and implementation status of previously identified issues in various workshops. By going to the actual site (Genba), observing the actual things (Genbutsu), and facing the actual situation (Genjitsu), the managers gained a more intuitive and profound understanding of how to apply lean concepts to practical work, and how to identify and solve problems.

In the afternoon, the activity moved into the thematic discussion and practical application phase. Participants engaged in in-depth technical discussions centered on the key topic of "Special Study on the Quality of Plain Weave Cloth and Aluminum Foil Cloth", jointly analyzing the current situation, exploring root causes, and establishing the next steps' action plans and follow-up measures. Subsequently, everyone observed the implementation of the initial cleaning phase of TPM and studied/coached on the related promotion posters, further solidifying the concepts of total participation and continuous improvement.

This guidance activity was not only a systematic knowledge training session but also a profound ideological mobilization. It perfectly illustrated the company's lean management system, which is built upon the solid foundation of "5S Management, Safety, TWI, and Total Participation", supported by the four pillars of "Proposal Topics, TPM, Standardization, and Process Quality". Through a full day of learning, inspection, and discussion, all management personnel gained a deeper appreciation for the lean spirit encapsulated in the phrase: "Holding ambition like heartache; introspection is the reliable path to solving our own problems."

At the conclusion of the event, Mr. Jiang provided summary comments on the day's activities and assigned follow-up improvement tasks. The successful execution of this activity not only enhanced the team's professional capabilities but also strengthened everyone's determination to follow the lean path, fortify the safety line, and pursue quality, injecting strong momentum into the realization of the company's long-term development vision.