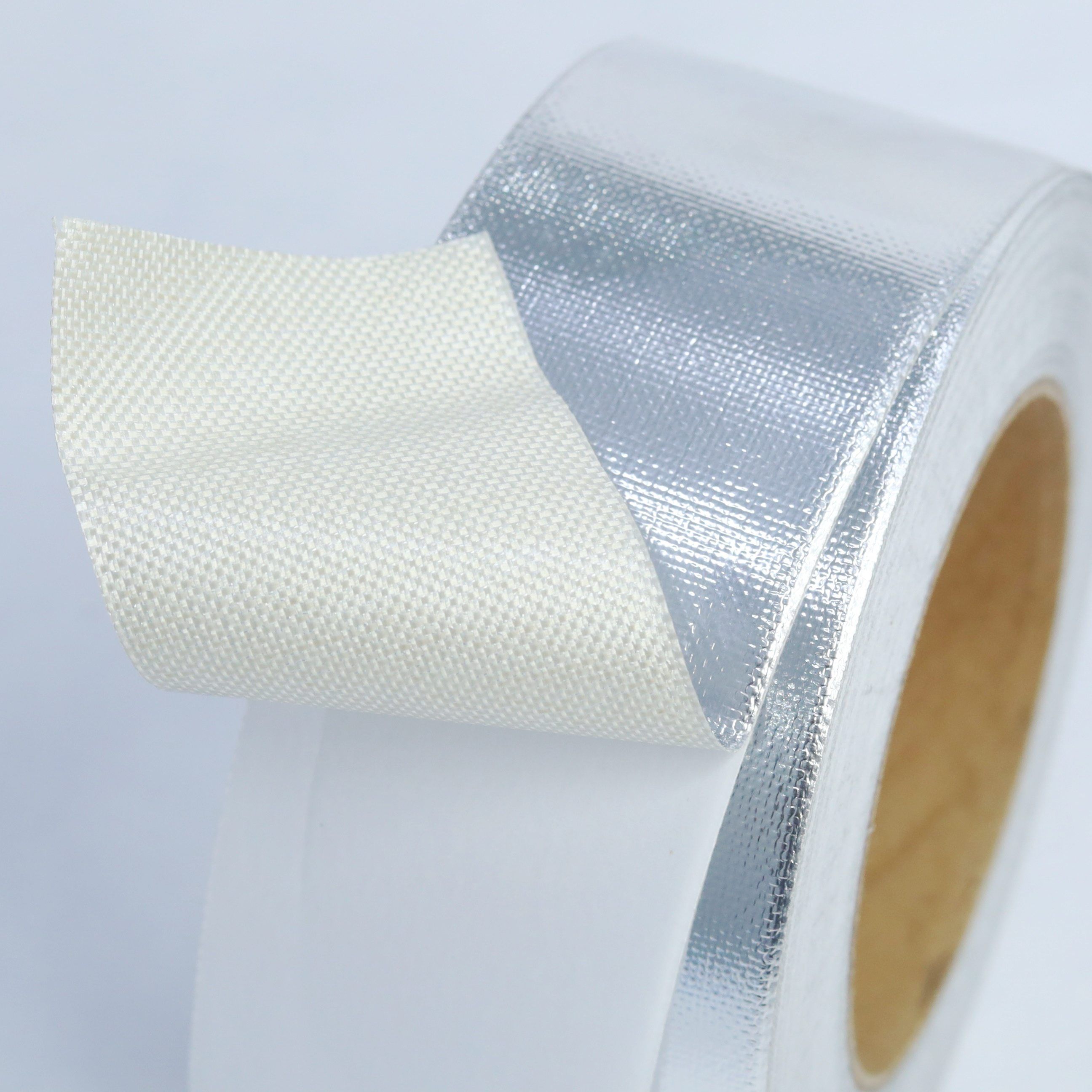

In the realm of industrial safety and fireproof insulation, every detail matters for the reliability and durability of the entire system. Aluminum Foil Fiberglass Cloth Tape, as a high-performance composite material, has become the preferred solution for engineers and professional users in critical applications, precisely because of its exceptional fire-resistant properties.

Core Advantage: Fire Performance That Exceeds Standards

The core value of Aluminum Foil Fiberglass Cloth Tape lies in its outstanding fire resistance. The product strictly complies with the highest fire safety standards, including GB8624-2006 and DIN4102 A1 class, achieving a flame spread rating of Class "1" and a surface spread rating of Class "2". It is particularly worth emphasizing that our high-end products can withstand temperatures up to 650°C. Even in extreme high-temperature environments, it maintains structural integrity, effectively slowing the spread of fire and buying valuable time for emergency response.

This exceptional fire performance stems from its precise material structure design. The product uses high-strength fiberglass cloth as the base, combined with high-purity aluminum foil through an advanced composite process. The multi-layer structure includes a waterproof layer, reinforcement layer, fiberglass layer, aluminum foil layer, and heat dissipation layer, all bonded together with precision technology to ensure performance stability under high-temperature conditions.

Comprehensive Performance Supporting Fire Resistance Advantage

While guaranteeing excellent fire performance, the product's other characteristics also provide strong support for fire safety:

Temperature Resistance

Aluminum Foil Composite Fiberglass Cloth: Heat resistance 260°C

Base Cloth for Aluminum Foil Fiberglass Tape: Heat resistance 550°C

Continuous Operating Temperature: Up to 650°C

Mechanical Properties

Tensile strength reaches 8000×6000N/5cm, ensuring it resists deformation or damage in complex stress environments, maintaining the integrity of the fire barrier.

Thermal Properties & Vapor Barrier

The aluminum foil surface has a high thermal radiation reflectivity of approximately 90%, a low thermal conductivity of 0.035W/mK, and a moisture vapor transmission rate of 0. These properties enable it to provide fire protection while completely blocking moisture penetration, preventing performance degradation due to dampness.

Professional Application Scenarios

In the field of building fireproofing and insulation, the product is widely used for insulating heating/cooling equipment pipes and as the protective outer layer for sound-absorbing/insulating materials like rock wool and centrifugal glass wool. It is particularly suitable for sealing puncture points caused by insulation pins on fireproof facings and for HVAC duct systems. In aluminum silicate fireproof wrapping systems, used as an outer covering material, it can provide different grades of fire resistance ratings such as 60, 90, and 120 minutes, fully meeting the stringent requirements of the Chinese national standard GB51251-2017 "Technical Standard for Building Smoke Control and Exhaust Systems."

In industrial pipeline insulation applications, the product is not only an ideal choice for HVAC ducts and hot/cold water pipes but is also widely used in critical sectors such as petroleum transmission pipelines, natural gas pipelines, and chemical/pharmaceutical equipment.

Selection Guide: Focusing on Fire Safety

Addressing the needs of professional clients, we recommend:

Select by Fire Rating

Ensure the material complies with national standards like GB8624-2006. For critical locations such as fire protection systems and smoke control/exhaust systems, prioritize products with higher fire ratings to ensure system safety and reliability.

Pay Attention to Temperature Resistance Matching

Choose products with corresponding temperature resistance grades based on the specific temperature requirements of the application environment. General building insulation may use products rated for 260°C, while industrial high-temperature pipelines require products rated for 550°C or higher specifications.

Mingyang Fiberglass: Professional Fiberglass Products Manufacturer

Mingyang Fiberglass (Jiangxi Ming Yang Glass Fiber Co., Ltd.), since its establishment in 2001, has grown into one of the leading producers of fiberglass and aluminum foil composite materials in Southern China. The company positions itself as a professional, full-category fiberglass manufacturer. Leveraging a comprehensive product line, it can meet the "one-stop" procurement needs of clients across various industries. The company's core business revolves around the production, processing, and development & sales of various functional fiberglass products. The product line ranges from basic fiberglass yarns to various fabrics, composite materials, and specialty tapes, widely used in construction, insulation, fireproofing, and other fields.

Whether you need to build safety barriers for new energy projects, seek breakthroughs in automotive lightweighting, or look for durable and reliable reinforcement materials in marine and construction sectors, Mingyang Fiberglass can provide you with comprehensive professional services, from material selection to application support.

Future Outlook

With technological advancements, we will continue to dedicate ourselves to enhancing the fire performance and reliability of our products, expanding applications in high-end fields like new energy and aerospace. In today's world where safety and energy efficiency are equally prioritized, choosing Aluminum Foil Fiberglass Cloth Tape with superior fire performance is not only a guarantee of project quality but also a responsibility for the safety of life and property.

If you need to learn more about our products or obtain customized solutions, please feel free to contact us.