What are the benefits of silicone fiberglass fabric?

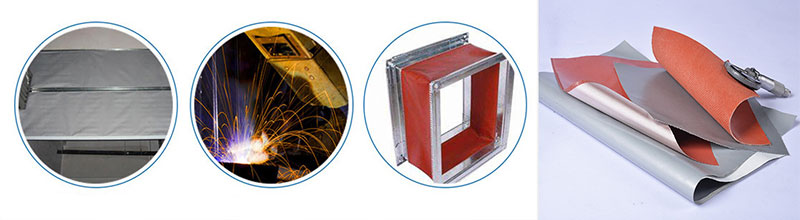

The silicone fiberglass fabric is made of glass fiber cloth as a substrate, which is coated with flame retardant silicone rubber and is made by a certain special process. Generally used in the pipeline soft connection. So how much benefit is there?

1. Silicone fiberglass fabric is flame retardant, its fireproof performance is superior, and its anti-aging performance is good. Because the pipeline is installed outdoors, it has to pass the test of sun and rain, and the silica cloth has certain anti-aging function.

2. Good thermal insulation performance, there is a certain high temperature steam in the pipeline, the temperature will not be emitted through the silicone fiberglass fabric. The sealing performance is good, the steam in the pipeline has a certain pressure, and the steam does not seep through the silicone fiberglass fabric.

3. The softness of the silicone fiberglass fabric is good, and it can be used for any soft connection with irregular shape.

![]()

Distribution lines can face harsh conditions. If standard products aren't doing the job and you need more protection for your standoff brackets and guy strains, look no further. Here are four reasons to switch to silicone-coated fiberglass construction products.

![]()

Distribution lines can face harsh conditions. If standard products aren't doing the job and you need more protection for your standoff brackets and guy strains, look no further. Here are four reasons to switch to silicone-coated fiberglass construction products:

Harmful UV rays – Silicone is UV resistant. For a piece of hardware on top of a distribution pole, having product with extra protection against the sun's rays is crucial.

Harsh environments – Silicone is extremely versatile – and tough. Silicone outperforms its standard paint-coated counterparts in every tough condition: snow, deserts, coastal areas, and corrosive environments. Silicone-coated products even reduce the risk of pole fires due to tracking.

Hydrophobicity - Silicone rubber compounds have a high degree of hydrophobicity, which means that water will run off (shed) much better.

Increase service life and improve reliability – This is really the sum of all the other parts – a product that resists everything from the rays of the noon sun at a high elevation, to a torrential downpour on the coast. Silicone coating results in longer-lasting products that do not warp, split, or shrink.

CHANCE® has extended its Fiberglass Construction Product line to include a silicone coated rod option, available for the complete guy strain offering (16,000, 21,000, 30,000 and 36,000lb) and for conductor support and equipment mounting standoff brackets with 1.5" and 2" rods. All products are shipped ready to install.

![]()

Why Use Silicone-coated Fabric over Polyurethane-coated Textiles or Genuine Leather?

Due to its crucial role in the production of textiles, silicone technology has revolutionized the textile industry. The modern discovery of silicone technology empowers textile producers to produce intelligent, high-performance, and functional textiles that can meet customer demands. The world of coated textiles is being upended by silicone chemistry, which has created a performance fabric that resembles leather in appearance and feels but is entirely different.

When searching for environmentally friendly coated textiles or leather substitutes, polyurethane and PVC-coated materials are no longer your sole choice. Silicone-coted fabrics are not only incredibly strong, but also have a contemporary appearance and feel, are solvent-free, and provide an environmentally friendly solution.

High-end products including outdoor furniture, car interiors, medical equipment, and athletic goods employ them to make performance fabrics.

Additionally, silicone coatings are safe for the skin and don't include any dangerous substances like phthalates or solvents. Since silicones are simple to work with, methods can be improved to use less total energy and/or material.

Why Silicone?

Silicones' practical advantages include:

Solventless

UV and ageing resistance

Resistance towards fire and heat

Temperatures both high and low don't affect flexibility

Good resistance against abrasion

Long-lasting adherence to a range of substrates

Silicone elastomers are a perfect material to use in conjunction with coated textiles because they make it possible to build composites out of several layers, each of which adds distinct qualities important to the performance, feel, and appearance on top of your preferred substrate. TCS products are specially selected and constructed to give excellent performance based on your intended end application.

The eco-friendliness of Silicone

Making an environmentally conscious decision by using silicone coated fabrics in your design is another benefit. Silicones are a resilient substitute for traditional plastics that protects the environment. Silicones are altering the way you see and develop high-performance coated fabrics, offering features like water and UV resistance, heat and fire protection, and eco-friendliness.

Conclusion

Silicone has influenced our lives in a variety of ways, and it may be found in a number of shapes. They are utilized for both commercial and fashion fabrics. For adhesives, bonding agents, textile coatings, lace coatings, and seam sealers, materials like elastomers and rubbers are employed. In addition to fiber lubricants and process aids, fluids and emulsions are employed for fabric finishes.

The world's industrial fabric manufacturers now have access to silicone technology to create specialized textiles and apparel that fully meet the practical requirements of contemporary lifestyles. Silicone technology is assisting textile makers in developing practical materials and high-performance textiles, regardless of whether the consumer is stylish, seeks comfort, or is cost-conscious.

Hot Tags: silicone coated (impregnated) fiberglass fabric, China, suppliers, manufacturers, factory, customized, cheap, low price, made in China, Fiber Glass Mesh For MgO Board, Best Screen Repair Tape, drywall fiberglass mesh tape, self adhesive mesh drywall tape, GFRP reinforcing fabric, cement board tape